Odours can be produced at several points within your business processes. Understanding your individual risks and available prevention measures is the only way to prevent odour pollution. Odour pollution is best caught at the source with fume hoods or extraction fans and treated directly. Your prevention measures will depend on your business and the type of odour you need to manage.

Where could odours be a problem in my business?

Below is a diagram outlining where you should perform odour emissions risk assessments at your business to determine whether prevention measures are required.

.png)

When and how odours could be produced

|

Receival

|

Processing

|

Waste

|

|

The receival and storage of raw materials poses a host of potential risks for the emission of odour pollution. Managing this process by keeping it indoors, electing to use a less odorous raw material where possible, or reducing the time materials spend exposed can help reduce the risk.

|

The processes or activities that happen as part of your business activities can emit odour. Containing these processes, or providing prevention measures to control the odour emissions from them can help reduce the risk.

|

The product, waste, or by-products that your business produces can also emit odour. It is important that you understand what type of waste or by-product you produce and the risks it can pose so that you can store, treat, or dispose of it correctly.

|

How do I know if I need to use odour prevention measures?

To determine whether you need to employ odour prevention measures at your site, you can perform a risk assessment in the same way you would for any other business risk. See Assessing and controlling risk: A guide for business (publication 1695). In the context of odour, a risk assessment would involve assessing how likely it is that odour pollution could occur at a site level. This would also help you tailor suitable prevention measures for your processes.

The first step is to assess the likelihood of a hazard causing harm. Likelihood is based on what is known about the hazard and the way circumstances and activities affect the hazard. Likelihood is ranked on a scale including: certain, very likely, likely, unlikely, and rare.

The second step is to work out the harm that each hazard could cause and how severe this harm could be. It is important to consider both the degree of harm with no controls in place (inherent or pre-control risk), and the degree of harm with existing controls in place (residual or post-control risk). In addition to this you should also consider written and actual procedures, people, community, property, and environment.

The final step, after considering likelihood and consequence, is to calculate a risk rating. These should be looked at together to create an overall risk rating. A risk rating is quantified by combining the severity of an event (consequence) and the probability of it occurring (likelihood) as

Risk = Consequence x Likelihood

It is recommended that risk assessments be performed collaboratively, encompassing each process that occurs at your site (receival, storage, transportation, and so forth). Please refer to the EPA guidance documents on risk assessments for a comprehensive guide on performing a risk assessment for odour pollution at your site.

What prevention measures can I use?

There are many different forms of odour prevention. The type of preventative measure you use will depend on a range of factors such as the size of your site and the severity of odours produced.

Hierarchy of control

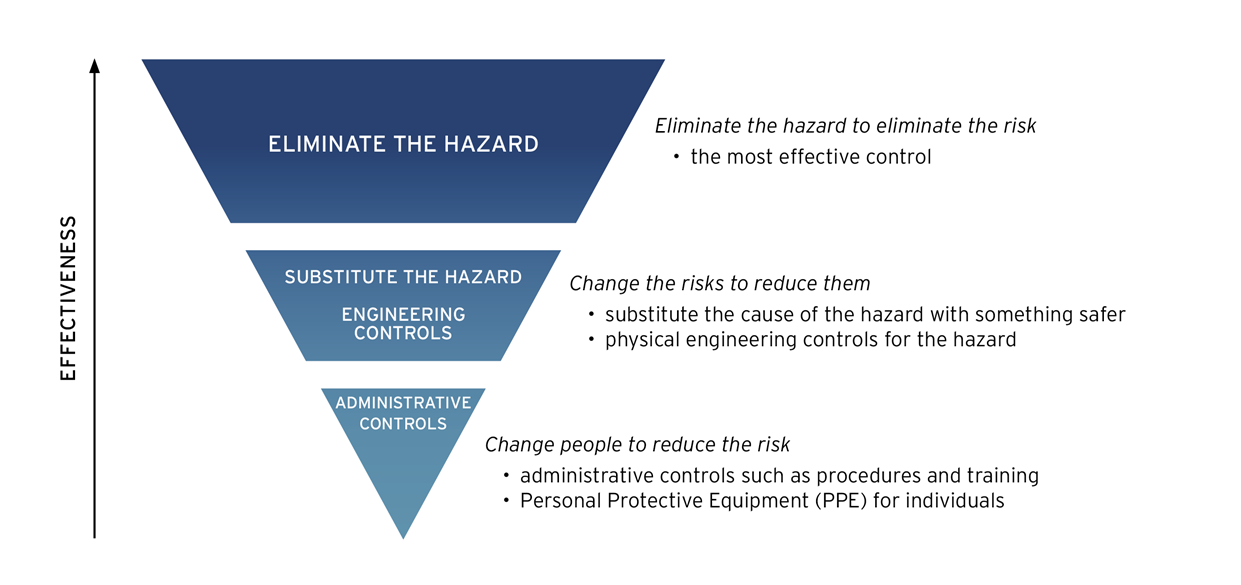

Following a hierarchy of control can be helpful when determining how effective the preventative measure used at your individual site is.

Click image to enlarge

Click image to enlarge

Key stages of odour prevention

To mitigate risk, it can be useful to implement prevention methods or ‘controls’; there are five key stages of odour prevention where controls can be implemented to address the odour at any business. Below you will find a list of controls within these five stages that may work for you. Each works in a different situation, usually in conjunction with other controls, and meets a different level of the hierarchy of control. Further information on the listed odour controls will be available as easily accessible fact sheets to be released in 2018 and 2019.

Contain

Any source that could produce an odour should be kept in a confined and contained area, preferably indoors wherever possible. In many instances this can eliminate the hazard, but is usually considered an engineering control.

Controls:

- site planning and management

- containment

- odour covers.

Capture

Odour emissions should be collected directly from the odour source. This is usually an engineering control, however, can act to eliminate the hazard with correct emissions treatment and release.

Controls:

- effective odour capture system.

Treat

Captured emissions and physical sources of odour should be treated to reduce their concentration or completely remove their odour where practical. Correct treatment can act to eliminate the hazard, but in some cases, is also considered a substitution or engineering control.

Controls:

- biofilters

- bio-trickling filters

- carbon filters

- metal sintered filters

- metal mesh filters

- thermal oxidizer

- chemical scrubbing

- ozone treatment

- effective microbes

- photoionization.

Release

An efficient system should be designed so any residual odour from emissions disperses and does not impact the public. A well-designed emissions system can eliminate residual odour and adopt an odour prevention process from engineering/substitution controls to complete elimination of the hazard.

Controls:

Monitor

Appropriate maintenance and monitoring of odour control equipment should be done regularly. This is generally considered an administrative level control, however, it is a necessary back-up for higher level controls.

Controls:

- site planning and management.