| This guidance sheet forms part of a series of guidance sheets on preventing and managing offensive odours, and should be read in conjunction with EPA Victoria’s Odour Guidance for Industry webpage. |

Description

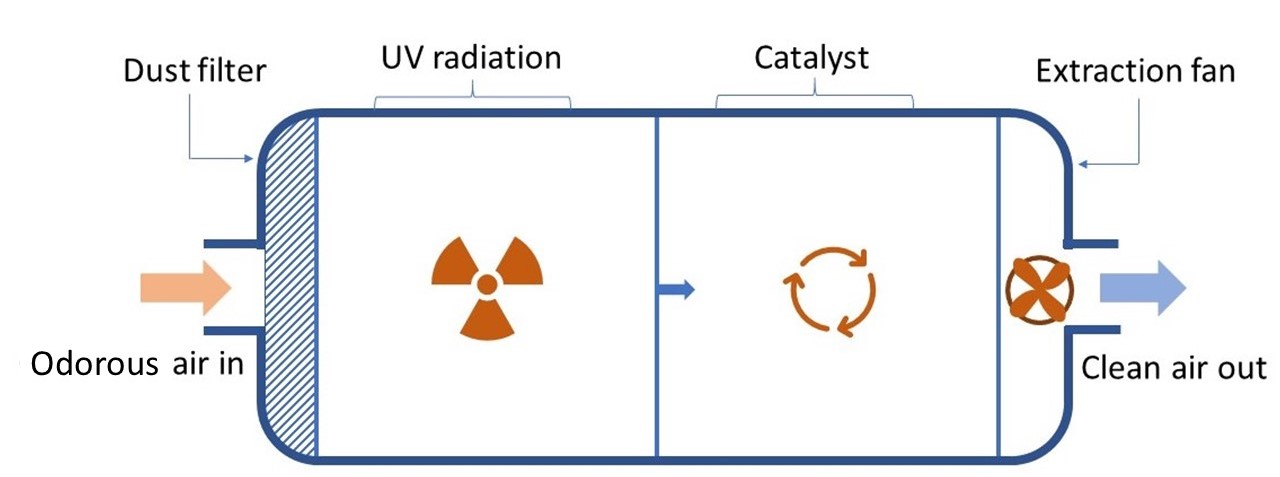

Photoionization is a relatively new odour elimination technique that works by exposing odorous air to ultra violet (UV) light, as well as titanium dioxide (TiO2) and other catalysts, in a controlled environment. The resulting UV radiation breaks down odorous compounds, reducing or eliminating odours. Air is also disinfected during this process and the by-products are considered benign.

Type of control

Physical and chemical.

When you would use this

Photoionization is often used in place of biofilters or chemical scrubbers. To determine if photoionization is appropriate for your site or business it could be beneficial to speak to a suitably qualified person. For assistance in selecting a suitably qualified person you can follow EPA Victoria’s guide on engaging a consultant.

Suitable for: photoionization can break down most organic odorous compounds, as well as many inorganic compounds.

Industries that would use this: most commonly used in waste, wastewater, sewage, dairy/animal effluent, and sludge treatment facilities.

Details and considerations

During the photoionization process, untreated air goes through a dust filter which removes fine particles. The air then enters the UV chamber where UV radiation begins breaking down many of the odour causing compounds. Next, the air comes into contact with a catalyst, which facilitates chemical reactions that finish breaking down odorous compounds, significantly reducing odour. The whole process is moved along by extraction fans creating negative pressure through the machine.

There are many reasons that photoionization could be beneficial for your business or site:

- Considered quite efficient, photoionization can treat over 95% of odorous compounds in exhaust, including both organic and inorganic compounds, and does not need a specialist to run once the system is installed.

- Photoionization can treat exhaust with varying concentrations of odour compounds, and does not require consistent input of exhaust. Systems can be switched on and off as needed.

- Although photoionization requires the use of a catalyst, the by-products of the photoionization process are considered benign. Additionally, maintenance and repairs are simple, parts replacement is generally needed every 1-2 years.

It should be noted that photoionization is a relatively new odour control system and is not as widely available as other odour control methods. This does not mean it is not worth investing in, however, it will mean that parts, upkeep, and suitably qualified maintenance professionals may be difficult to find in your area.

Further information

This is such a new technology there is not currently any further information or Australian standards.